AN ECO-FRIENDLY APPROACH TO STRETCH FILM

WE REDUCE THE ENVIRONMENTAL LOAD

Eco-friendly stretch film

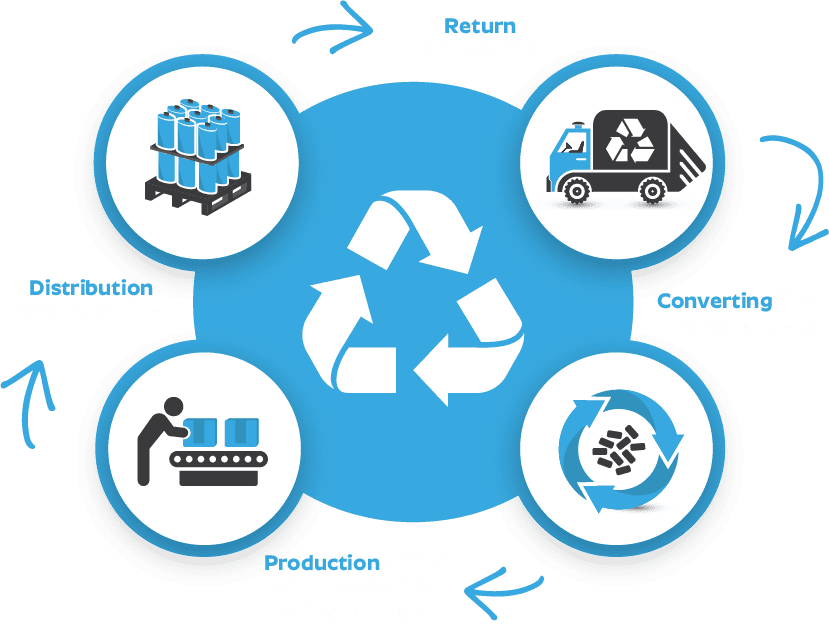

We produce eco-friendly stretch film, which is made from recycled raw materials.

Waste-free production

We collect all the offcuts that are generated during film production and process them into regranulate.

Reducing CO2 emissions

We use waste heat from the production line to warm the water up.